Resource Person/ Facilitator: Mr SIDHARTH GIRISH AYACHIT

Summary:

1. Introduction

The Department of Electrical Engineering of Zeal Polytechnic, Narhe, Pune organized an industrial visit to Drona Transformer Pvt. Ltd., Bhosari MIDC, Pune. The visit was conducted to provide students with real-time exposure to transformer manufacturing, testing, and maintenance processes. This industrial visit formed an essential part of experiential learning, bridging the gap between theoretical concepts studied in the classroom and their practical implementation in industry.

2. Company Profile: Drona Transformer Pvt. Ltd.

Drona Transformer Pvt. Ltd., located in Bhosari MIDC, Pune, is a reputed company engaged in the design, manufacturing, repair, and servicing of electrical transformers. The company specializes in:

- Power Transformers

- Distribution Transformers

- Special Purpose Transformers

- Transformer Testing & Maintenance Services

The organization is well-equipped with modern machinery and a skilled workforce, ensuring adherence to international standards of transformer design and testing.

3. Activities & Work Exposure During the Visit

During the industrial visit, students were guided by company experts through different departments and processes:

1. Design Section

- Introduction to transformer design considerations such as capacity, losses, insulation level, and efficiency.

2. Core Assembly

- Observation of the cutting, stacking, and assembly of CRGO (Cold Rolled Grain Oriented) steel laminations used in transformer cores.

3. Winding Section

- Demonstration of copper and aluminum winding with proper insulation techniques.

- Understanding of HV (High Voltage) and LV (Low Voltage) winding methods.

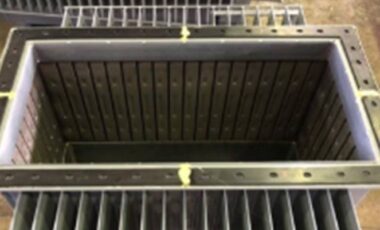

4. Tank Fabrication Section

- Explanation of transformer tank manufacturing and importance of oil cooling systems.

5. Insulation & Assembly

- Knowledge about insulation materials and techniques to withstand dielectric stress.

6. Testing Laboratory

- Students observed routine and type tests such as:

- Insulation Resistance Test

- Ratio Test

- No-Load Test

- Short-Circuit Test

- Oil BDV (Breakdown Voltage) Test

7. Quality Control & Dispatch

- Insights into quality assurance practices and final inspection before dispatch.

4. Skills Gained by Students

- Practical understanding of transformer design and manufacturing processes.

- Exposure to industrial standards, quality checks, and testing methods.

- Knowledge of winding techniques and insulation systems.

- Improved confidence in applying classroom knowledge to industrial applications.

- Awareness of safety measures in handling high-voltage equipment.

5. Outcomes of the Visit

- Students acquired first-hand industrial experience of transformer production and testing.

- Enhanced practical knowledge and technical problem-solving skills.

- Developed understanding of industry practices and career opportunities in the electrical sector.

- Strengthened industry-institute relationship for future internships and placements.

6. Conclusion

The industrial visit to Drona Transformer Pvt. Ltd. was a highly enriching experience for the students. It provided practical insights into the complete process of transformer design, manufacturing, assembly, and testing. The visit successfully bridged the gap between theoretical knowledge and real-world industrial practices. Students gained valuable technical knowledge, professional exposure, and motivation for their future careers in the electrical engineering domain.

Objective/Purpose:

- To understand the manufacturing process of power and distribution transformers.

- To gain knowledge about testing and quality assurance techniques used in transformer industries.

- To observe different types of winding arrangements, core assembly, and insulation techniques.

- To develop an understanding of the practical challenges and industrial practices in transformer design and production.

- To enhance students’ industry readiness and technical competency.