Resource Person:

- Kiran Kharmale, (Managing Director)

- Manish Kharmale

- Mrs. Pooja Shinde (HR)

Industry Profile:

- Samruddhi Engineering is a recognized and trusted name in the field of CMM Inspection Services and Precision Gauge Manufacturing. Located in the prime industrial zone of Bhosari MIDC, Pune, Samruddhi Engineering is committed to delivering high precision, top quality, and dependable services in all operations.

- Samruddhi Engineering has a team of highly skilled and experienced professionals, supported by modern and advanced technology. This enables the company to provide accurate results, timely delivery, and maximum efficiency for every project undertaken.

- The CMM Inspection Services offered by Samruddhi Engineering are designed to meet the stringent quality requirements of various industries. The company provides a complete range of inspection solutions including dimensional inspection, GD&T (Geometric Dimensioning & Tolerancing), and reverse engineering. With expert knowledge and technical proficiency, Samruddhi Engineering handles even the most complex inspection tasks with precision.

- In addition to inspection services, Samruddhi Engineering specializes in the manufacturing of precision gauges tailored to customer needs. From simple Go/No-Go gauges to advanced multi-dimensional gauging systems, the company uses its technical expertise and industry experience to deliver customized solutions that consistently exceed client expectations.

- What sets Samruddhi Engineering apart is its strong commitment to perfection and customer satisfaction. The company understands the critical role of precision in clients’ operations and focuses on providing services that surpass industry standards. As a dependable partner in quality assurance and precision engineering, Samruddhi Engineering aims to build long-term relationships based on trust, reliability, and consistent quality.

Products:

1. CMM Inspection Services

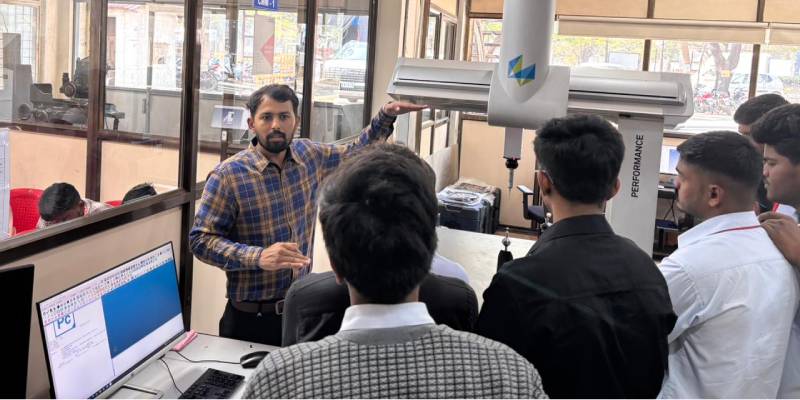

Samruddhi Engineering offers comprehensive Coordinate Measuring Machine (CMM) inspection services that meet stringent industrial quality requirements. The company uses advanced CMM machines including ZEISS CONTURA G2, HEXAGON GLOBAL PERFORMANCE, and HEXAGON OPTIV LITE VISION.

Facilities Available

- 2D & 3D Inspection

- CAD Model Comparison

- Geometric Dimensioning & Tolerancing (GD&T) Verification

- Scanning and Digitization

- Gear Inspection

- CAM Drum Inspection

- 2 Machine Capabilities

- High accuracy ranging from 1.9 microns to 3 microns

- Large machine sizes capable of handling various components

- Software platforms like CALYPSO, PCDMIS CAD++, and PCDMIS

Industries Served

- Automotive

- Aerospace

- Heavy Engineering

- Tool & Die

- General Manufacturing

2. Precision Gauge Manufacturing

Samruddhi Engineering specializes in designing and manufacturing a wide range of precision gauges to support dimensional verification needs.

2.1 Standard Gauges

- Plain Plug & Ring Gauges

- Snap Gauges

- Air Gauges

- Flush Pin & Depth Gauges

- Thread Plug & Thread Ring Gauges

- Measuring Pins

- Groove & Width Gauges

2.2 Special Gauges

- Concentricity Gauges

- Profile Checking Gauges

- Land Relation Gauges

- Length Gauges (Crankshaft)

- OD/ID Checking Gauges

- Squareness & Parallelism Gauges

- Holding Fixtures

2.3 Custom Gauge Solutions

Samruddhi Engineering also provides custom-designed relational gauges and fixtures based on customer drawings and requirements.

3. Tool Room Services

The company offers complete tool room solutions from conceptual design to final manufacturing of inspection fixtures and gauges.

3.1 Services Include

- Design and development of gauges and fixtures

- Fabrication of inspection holding fixtures for CMM

- Manufacturing of master and reference gauges

- Precision machining services

3.2 Applications

- Dimensional Inspection

- Assembly Checking

- Quality Verification

Objective/Purpose:

- To understand the working and applications of CMM inspection systems.

- To observe real-time dimensional inspection and GD&T practices.

- To study the manufacturing process of precision gauges.

- To learn about CAD model comparison and scanning technology.

- To familiarize students with industrial measurement standards and procedures.

- To gain practical exposure to tool room operations and fixture manufacturing.

- To enhance technical knowledge related to quality control and verification.

- To connect theoretical concepts with actual industrial applications.