Date:

Div: A 09/09/2025 Time: 10.30 pm -01.30 pm Present Students: 63

Div: B 10/0902025 Time: 10.30 pm -01.30 pm Present Students: 45

Div: C 11/09/2025 Time: 10.30 pm -01.30 pm Present Students: 63

Resource Person: Mr. Swapnil Bhagare, Executive HR- Admin

Summary:

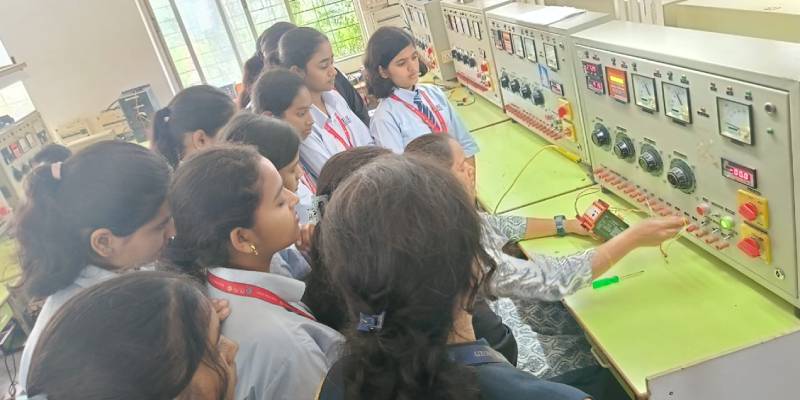

The Department of Electronics and Telecommunication organized an industry visit to Minilec Industry, a leading company in the field of electronic control and protection devices. Students from Second Year Diploma (Divisions A, B & C) participated in the visit on three consecutive days. The visit aimed to bridge the gap between classroom learning and industrial practices. Students observed various stages of product development, design, and quality testing of electronic relays and controllers. The session provided practical exposure to industrial safety standards, quality management, and automation systems.

Minilec offers the widest, most extensive and reliable line of Motor & Pump Protection relays, Phase Failure Relays, Microprocessor Based Annunciation & event-monitoring Systems for today’s industrial markets worldwide. Minilec has traditionally been the leading producer of phase failure relays, motor protection relays since the late 1960s. Today our products have been recognized as the best in Quality, Delivery and Customer satisfaction. Over the years it has diversified into three major verticals namely Electronics, Surface Coating, and Materials Handling, establishing popular brands like Minilec, Statfield Equipment, and Intech Surface Coating.

Objective/ Purpose:

Minilec India Pvt. Ltd. is a company based in India that specializes in providing solutions related to electrical and electronic systems. Minilec India Pvt. Ltd. company typically aims to achieve specific objectives that align with its mission and vision.

Objectives:

- To provide students with hands-on exposureto industrial working environments.

- To understand the manufacturing process of protection relays and control devices.

- To relate theoretical knowledgeof electronics with practical applications.

- To develop awareness of industrial safety standards, quality assurance, and teamwork.

- To motivate students for innovation, skill development, and professional growth.

Outcomes:

- Students gained knowledge of industrial processes and workflows.

- Understood the importance of automation, protection circuits, and control systems.

- Observed the role of testing and quality controlin ensuring product reliability.

- Improved their professional outlook, discipline, and teamwork skills.

- Strengthened their industry-institute interaction for future career opportunities.